venturi flow meter working principle

The fluid whose flow rate is to be measured enters the entry section of the venturi meter with a pressure P1. The Venturi flow meter is a combination of a Venturi tube a differential pressure transmitter and a valve block.

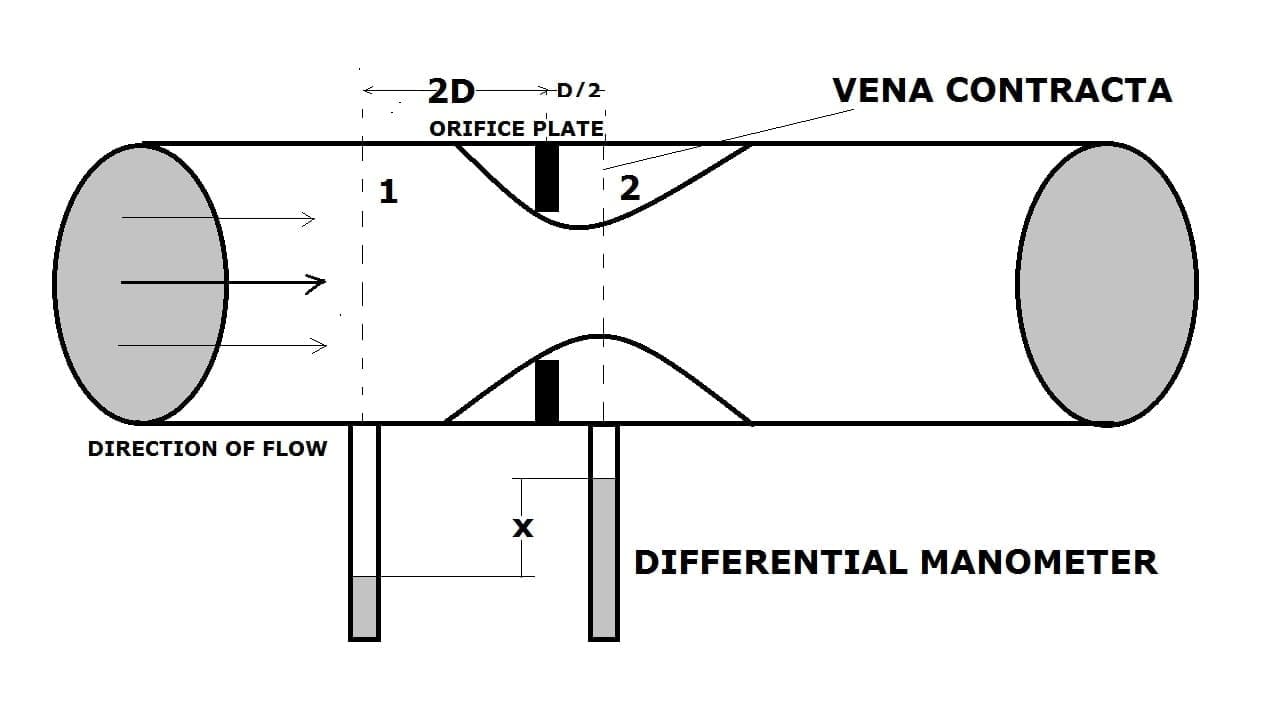

Orifice Meter Definition Construction Working Experiment Derivation Formula Advantages Application Notes Pdf

With no moving parts or abrupt flow restrictions the Venturi can measure fluid flowrates with a minimal total pressure loss.

. Venturi flowmeter working principle. 2 it gives higher accuracy and hence it is generally used where higher accuracy is required. The Venturi flow meter produces a differential pressure to calculate the flow rate through a pipe.

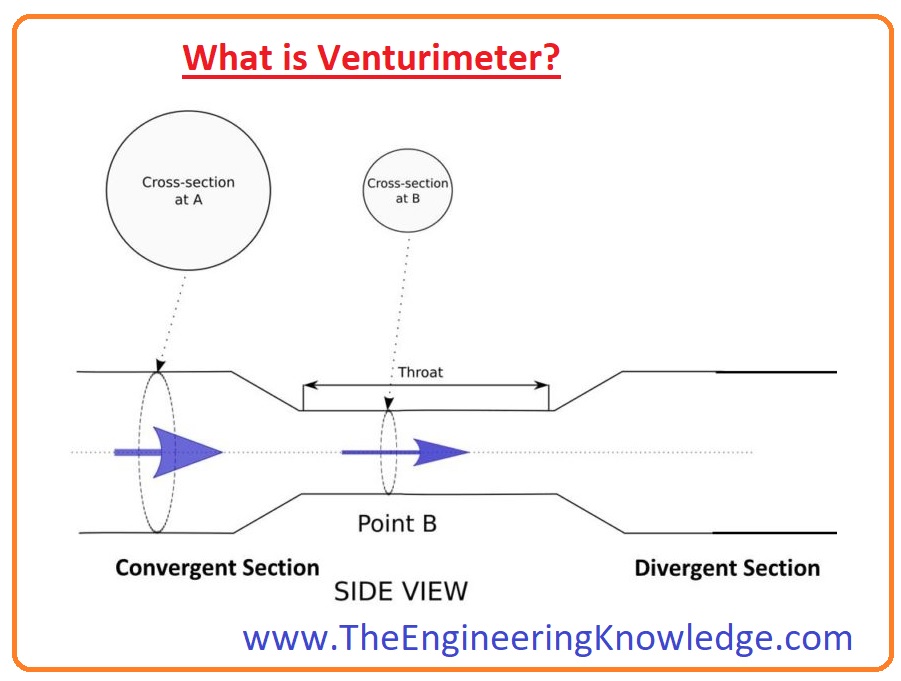

Working Operation of venturi meter. The cross-section of the throat is less than the cross-section of the inlet pipe. The meter can measure the fluid flow and reduce its flow when necessary.

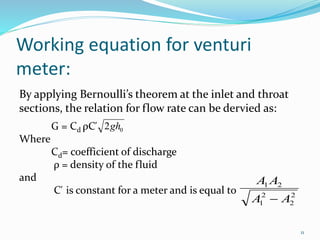

This alteration in pressure is calculated with the assistance of a manometer pressure measuring device and. Let P 1 is the pressure in the inlet section P 2 is the pressure in the throat section v 1 is the velocity of the fluid passing through the inlet section v 2 is the velocity of the fluid passing through the throat section ρ is the density of the liquid and A 1 and A 2 be the area of the cross-section at inlet section. Venturis deliver fixed stable repeatable flow rates.

Piping and fittings should be made of corrosion resistant materials such as stainless steel or Plastic. That is in the throat the fluid pressure P2 will be minimum. A Venturi flow meter is a differential pressure flowmeter.

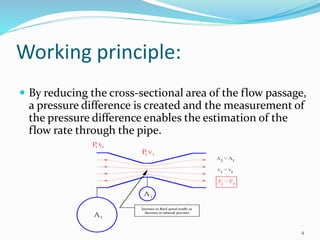

Inner side of the pipe pressure variance is produced by dealing the cross-sectional area of the movement passageway. Venturi Meter works on the principle of Bernoullis equation. Venturimeter is a type of flowmeter that works on the principle of Bernoullis Equation.

The meter works by measuring the pressure of fluid before and after it passes through a narrow tube. 1 In industrial pipes to measure flow rate of liquid and slurry. Since the cross -section decreases from inlet pipe to throat the velocity of the fluid increases and hence the pressure decreases.

The venturi meter is placed in a pipe carrying the fluid. The fluid whose flow rate is to be measured enters the entry section of the venturi meter with a pressure P1. A venturi meter is an instrument which is to calculate the liquid flow in tubes.

In modern applications the principal advantage of the. Cross section of throat is less than cross section of inlet pipe. Working -Venturimeter works on the principle of Bernoullis equation ie when velocity increases pressure decreases.

When fluid passes through different cross-sections of a venturi meter it undergoes different levels of strain. The principle behind the operation of the Venturi meter or venturi tube is the Bernoulli effect as well as the Continuity equation. As the cross-section from the inlet pipe to the throat decreases the velocity of the fluid increases and hence the pressure decreases.

Venturi Flow Meter. The pressure difference indicates the volumetric rate of flow. The Venturi measures a fluids flowrate by reducing the cross sectional flow area in the flow path and generating a pressure difference.

Venturi Meter Working Principle. Fluid flow is calculated when the meter checks the pressure difference between the two readings and the temperature. The principle of venture meter is firstly developed by GB.

Operation of venturi meter. Venturi Meter is a device in which pressure energy is converted into kinetic energy and it is used for measuring the rate of flow of liquid through pipes. Venturi flow meters are often used to measure the flow of fluids such as air natural gas coal gas and water.

It works on the basic principle of Bernoullis Equation. Differential pressure flow gauges cause a narrowing in the pipe that creates a decrease in pressure across the flow gauge. It is invented by American Engineer Clemans Herchel and named by the Italian physicist Giovanni Venturi.

As the fluid from the entry section of the venturi meter flows into the converging section its pressure keeps on reducing and attains a minimum value P2 when it enters the throat. Working Principle of Differential Pressure Flow Meter Previously it has been mentioned that this DP Flow Meter uses bernoulli law to measure fluid flow in pipes. The principle behind the operation of the Venturi flowmeter is the Bernoulli effect.

Piping should have a slope of at least 1 per foot. The Venturimeter working principle is based on Bernoullis theorem. This strain difference is measured with the assist of a manometer which helps determine the rate of fluid flow through the pipe.

The venturimeter is attached to a pipe using flanges so that the fluid which is flowing through the pipe also flows through a venturimeter. This meter is works on the principle of Bernoullis equation. For years of reliable service BIF recommends the following.

Written by Anup Kumar Dey in Instrumentation Mechanical Pipeline Piping Design Basics Piping Interface. 3 it is used in applications where high pressure recovery is necessary. The restriction diameter should not be less than 0224 D and not more than 0742 D where D is the nominal bore diameter of the pipe.

The principle is that when cross sectional area of the flow is reduced then a pressure difference is created between the different areas of flow which helps in measuring the difference in pressure. The venturimeter works on the principle of Bernoullis equation ie the pressure decreases as the velocity increases. In the venturi meter the fluid flow rate is reduced due to the reduction of the cross-sectional area.

This device is widely used in the water chemical pharmaceutical and oil gas industries to measure the flow rates of fluids inside a pipe. Ad Designed And Manufactured To Asme Section Iii Class 1 2 3 Or Customer Specified Code. Venturimeter working principle- Venturimeter is an instrument which is used to measure average velocity of a flowing fluid or flow rate of a flowing fluid.

To measure the flow rate that is discharged a pressure drop occurs between the entrance and throat of the venturi meter. Install an isolation valve close to the high and low-pressure connections. As the fluid from the entry section of venturi meter flows into the converging section its pressure keeps on reducing and attains a minimum value P2 when it enters the throat.

It is often used to measure the flow of pressure pipes. Engineers can measure the change in pressure using Venturi meters and nozzles which tell you the flow rate. Venturi in 1797 but this principle comes into consideration with the help of C.

A venturi tube contains a throat which is smaller in a diameter to the pipeline into which it fits. The venturimeter is generally used in following applications. Key Parts Of Venturimeter.

Any point of flowing fluid in the venturi meter there will be pressure energy potential energy and kinetic energy.

Venturi Flow Meter Working Principle Animation Instrumentationtools

Flow Measurement Powerpoint Slides

Flow Measurement Powerpoint Slides

Venturimeter Definition Parts Working Principle Derivation Applications Advantages And Disadvantages The Engineering Knowledge

What Is Differential Pressure Flow Meter Instrumentationtools

Venturi Flowmeter Flowmaxx Engineering

Venturi Flow Meter Working Principle Animation Instrumentationtools

Pipe Flow Measurement Venturi Flowmeters Bernoulli S Equation

Venturi Flow Meter Working Principle Animation Instrumentationtools

Venturi Meter Construction Working Equation Application Advantages And Disadvantages Mecholic